摘要

随着计算机技术的发展以及工业自动化水平的不断提高,利用计算机技术对生产进行管理以及对生产过程实施数据采集和监控,越来越受到人们的关注。

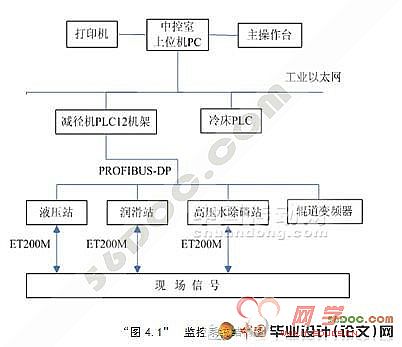

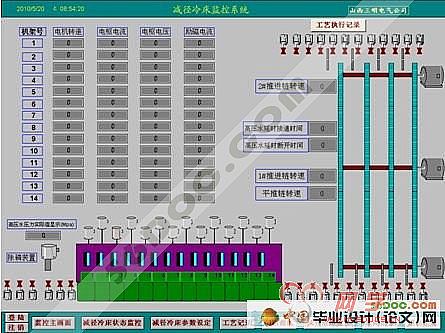

本文首先介绍了无缝钢管、无缝钢管生产线、减径机以及工业监控系统;然后介绍了组态软件的特点、构成以及各种组态软件的对比,和Win cc的优点、特征;最后详细叙述了利用Siemens公司的WinCC组态软件对无缝钢管生产中的减径机、冷床部分进行监控的设计,截取了主要监控画面并加以说明。

该设计的特点是故障响应快,操作简单,组态画面丰富等,减少了工人的劳动强度,保证了无缝钢管生产的连续性,大大提高了生产效率。

关键词:无缝钢管,减径机,组态软件,Win cc,监控系统

Abstract

With the development of computer technology and continual promotion of factory automation,more and more attention is paid to administration of factory information and data collection and monitor during industrial producing by means of computer technology.

This article first introduced the seamless steel pipe, the seamless steel pipe production line, reduces the diameter machine as well as the industry supervisory system; Then introduced the configuration software''s characteristic, the constitution as well as each kind of configuration software''s contrast, with Win cc merit, characteristic; Finally narrated in detail has used Siemens Corporation''s WinCC configuration software to reduce the diameter machine to the seamless steel pipe production, the cold-frame part to carry on the monitoring the design, has intercepted the main monitoring picture and explained. 〖毕业设计(论文)咨询QQ:306826066〗

This design''s characteristic is the breakdown responds quickly, simplicity of operator, configuration picture rich and so on, reduced worker''s labor intensity, had guaranteed the seamless steel pipe produces the continuity, raised the production efficiency greatly.

Keywords: Seamless steel pipe; Reduces the diameter machine ;Configuration; Win cc; Monitoring system 〖资料来源:毕业设计(论文)网 http://www.〗

目 录 23000字

第1章、绪论 1 〖毕业设计(论文)咨询QQ:306826066〗

1.1无缝钢管及无缝钢管生产线简介 1

1.1.1无缝钢管生产制造方法简介 1

1.1.2无缝钢管用途 2

1.1.3无缝钢管种类 2

1.1.4无缝钢管物理性能检测 2

1.2无缝钢管生产线简介 2

1.2.1热轧无缝钢管 2

1.2.2冷轧无缝钢管 3

1.2.3无缝钢管生产线各部分介绍 3

1.3减径机简介 6

1.4冷床简介 6

1.5工业监控系统 7

1.6课题研究的目的和意义 8

第2章、组态软件 9

2.1组态软件概述 9

2.2监控组态软件特点 9

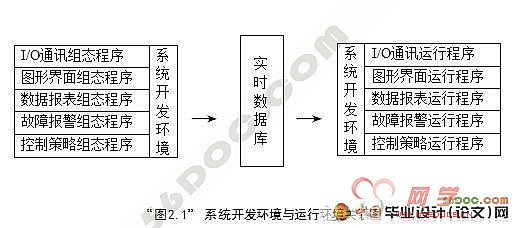

2.3组态软件构成 10

2.4常用组态软件对比介绍 11

2.5组态软件的功能特点发展方向 13

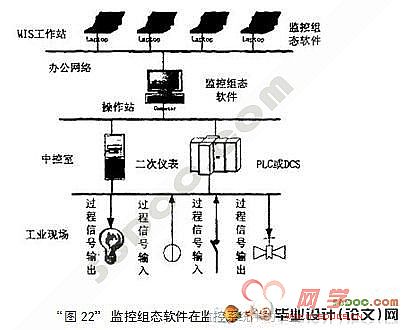

2.6组态软件与监控系统的关系 16

第3章、西门子Win cc介绍 18

3.1西门子Win cc概述 18

3.2 Win cc系统概览 23

3.3 Win cc优点 24

3.4 Win cc的特征 25

〖资料来源: 毕业设计(论文)网〗

〖资料来源:毕业设计(论文)网 www.〗

< class="3835